Do you take refrigeration for granted? You’re certainly not alone. It feels so normal to reach into the fridge to grab fresh produce or a cold drink. In reality, however, this ability is relatively new. For millennia, humans dealt with the constant challenge of spoilage.[1]

Do you take refrigeration for granted? You’re certainly not alone. It feels so normal to reach into the fridge to grab fresh produce or a cold drink. In reality, however, this ability is relatively new. For millennia, humans dealt with the constant challenge of spoilage.[1]

With fridges present in the vast majority of U.S. households, there’s no denying their influence in daily life, and yet, the complex mechanisms that preserve our food remain widely misunderstood.[2]

This is where the refrigeration cycle comes into play. Featuring a series of precisely coordinated processes, this reveals exactly how heat moves from within the fridge to other spaces, ensuring that the fridge remains a consistently cool environment in which food and beverages remain fresh and safe to consume.

What Is the Cycle of Refrigeration?

Understanding the cycle of refrigerators is essential to optimizing how modern fridges operate and consume energy. This effort is dominated by a sequence known as the cycle of refrigeration.[3]

Although often discussed in the context of air conditioning, this cycle is relevant to operating household refrigerators, as it draws on similar thermodynamic principles and key mechanisms such as compressors and condenser coils. We’ll break down the most important elements of this cycle in detail below:

Superheat and Subcooling

Complementary processes known as superheat and subcooling bring a sense of balance to refrigerators, allowing them to run reliably and efficiently over time. Superheat describes the differences between a vapor’s actual temperature and its saturation temperature (at which the refrigerant switches between liquid and vapor states). This ensures that only vapor is compressed, thereby protecting the compressor.[4]

Subcooling describes how the refrigerant cools below the saturation temperature. This is important because it prevents vapor from entering expansion valves.[5] Together, the concepts of superheat and subcooling function as means of measurement, as these details can provide critical insight into concerns such as system capacity.[6]

Air Temperature

The internal air temperature offers a key indication of cooling effectiveness. This determines how cold food and beverages stored within the fridge can get, revealing the impact of the refrigeration cycle.

This should not be confused with the refrigerant temperature, which reflects processes that occur within the coils. According to the Food and Drug Administration (FDA), fridge temperatures should not exceed 40 degrees Fahrenheit.[7]

Suction Pressure and Head Pressure

The process of absorbing heat within an evaporator produces a low-pressure vapor. This type of pressure is called suction pressure. This offers a glimpse at how evaporators absorb heat or whether there is enough refrigerant in the system. Low suction pressure is associated with refrigerant undercharge, while high suction pressure indicates less-than-ideal heat absorption.[8]

Another critical concept involves the head pressure, which focuses on the condenser’s heat rejection. Also known as the discharge pressure, this describes the refrigerant’s pressure on the system’s high-pressure side. If the head pressure is high, overcharging or airflow issues are likely. Low head pressure could indicate issues with the compressor.

How Does the Refrigeration Cycle Work?

The refrigeration cycle follows several essential steps to ensure that heat is properly transferred away from the fridge’s interior and into the surrounding space, thereby allowing the fridge and its contents to remain cool.[9]

Compression

As the core component that drives refrigeration systems, the compressor pressurizes the refrigerant, functioning much like a pump to move the refrigerant within the system. This component works closely with the condenser to ensure high-pressure gas can efficiently release its heat.[10]

Condensation

Naturally occurring in humid environments, condensation occurs as air cools, creating water droplets or even ice. In a fridge, this process is driven by a condenser, which forms the basis for heat exchange.

Expansion

As a critical process between the better-known phenomena of condensation and evaporation, expansion takes the high-pressure liquid from the condenser. It drops the pressure, causing the refrigerant to expand. This then causes the refrigerant to expand in volume and facilitates a shift in state from liquid to vapor.

Evaporation

Evaporation takes place when a low-pressure (and recently expanded) refrigerant absorbs heat from within the fridge. This turns the refrigerant into vapor. This is the most recognizable aspect of refrigeration, as it’s where the actual act of cooling takes place.

Cycle Repeats

The stages highlighted above (compression, condensation, expansion and evaporation) occur repeatedly to ensure that heat continues to transfer from within the fridge to the outside space. Without a cyclical approach, the evaporator would eventually be unable to absorb extra heat, thereby halting the cycle of heat transfer.

Key Areas for Refrigeration Cycle Optimization

While the refrigeration cycle plays a vital role in keeping foods and beverages safe to consume, there is a major caveat, as this process can be incredibly wasteful if not fully optimized.

Throughout the refrigeration cycle, there are numerous opportunities for heat loss, such as poorly insulated walls or leaky seals. This makes components work harder to maintain desired temperatures, thereby using even more energy. Thankfully, there are many ways to optimize refrigerator cycles while limiting waste:

Increase Component Efficiency

Every refrigerator component contributes to the big picture of efficient and reliable temperature control. Individual improvements to these components can lead to significant changes in overall efficiency.

Compressors, Condensers, Evaporators and Metering Devices

Compressors and condensers are among the most impactful components within modern refrigerators, so it should come as little surprise that these can also be the most significant sources of waste. Variable-speed compressors can boost efficiency by operating based on cooling demand.

The evaporator’s impact must also be considered. Ideally, airflow will be optimized to promote uniform cooling, thereby preventing potentially wasteful hot spots. If properly calibrated, metering devices can limit waste by ensuring that refrigerant consistently enters evaporators at the proper pressure.

Improve Control Systems

Influencing everything from fans to defrosting, and, of course, the temperature within the fridge, control systems regulate the refrigeration cycle to enable both consistency and efficiency.

While these may encompass mechanical mechanisms, recent advancements have delivered greater precision, thereby improving convenience and even sparking dramatic improvements in efficiency.

Advanced Control Systems and Monitoring Apps

Today’s smart fridges use sensors to monitor energy use, detecting changes in temperature along with the volume of food stored in the fridge and even the door status. These solutions can optimize efficiency by adjusting cycles according to actual usage. Meanwhile, smart diagnostics promise early detection, ensuring that small issues are addressed quickly to prevent costly repairs down the road.[11]

Operational Improvements for Refrigeration

While efficiency is largely built into the structure of the modern refrigerator, this can be further enhanced through operational strategies that promote optimal cooling. This goes beyond the basic components to address overall performance within the context of the refrigeration cycle. Each stage must work in harmony. Basic operational improvements can achieve this by promoting consistency and efficiency.

Maintenance, Insulation, Demand Management and Temperature Adjustment

Refrigerators require regular maintenance, including cleaning and component checks. Homeowners can handle some tasks, but others may call for additional expertise.

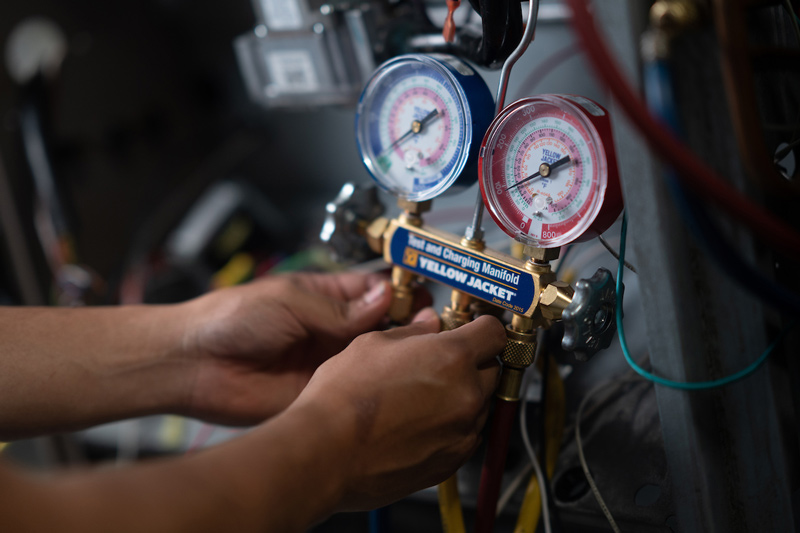

Technicians check refrigerant levels, evaluate electrical systems or address mechanical concerns surrounding the compressor. They may promote insulation by inspecting for gaps or boosting demand management via smart controls and sensors. By calibrating thermostats, they can achieve desired temperatures without risking overcooling.

Improving System Design

Refrigeration system design examines the overarching structure of a refrigerator, rather than just the individual components and their specific functions within the refrigeration cycle. This holistic approach reveals how the overall architecture can impact efficiency, either positively or negatively. This involves the layout of the various components discussed above, but also calls for strategic decisions surrounding airflow management.

Structural Modifications and Sizing and Recovery

Sizing has a huge impact on a refrigerator’s overall energy consumption. Naturally, larger fridges will use more energy, while smaller appliances may allow for greater efficiency. Beyond this, there is a strong need to strike the right balance between the interior volume and the sizes of the individual components.

Structural modifications can further reduce the load on refrigeration systems, reducing, for example, warm air exchange while allowing cold air to flow freely. Insulation, seals and gaskets are all important, as these limit the potential for heat intrusion — the unwanted transfer of heat.

Improving Refrigeration Energy Efficiency

With consumers now prioritizing efficiency, manufacturers are placing a greater emphasis on designs and mechanisms that limit energy usage. The quest for peak efficiency relies heavily on operational practices but also encompasses maintenance and even door management.

Operational Practices

Energy efficiency should be built into every aspect of refrigeration systems, including their core operations. This means optimizing temperatures, but without overworking the compressor. Meanwhile, airflow management promotes even distribution of air.

Air Circulation and Door Management

Proper air circulation distributes cold air evenly throughout all compartments, ensuring that the entire interior of the fridge remains sufficiently cool. Unobstructed pathways are essential, as are clean and properly functioning fans.

Door management acknowledges the reality that, whenever the refrigerator door is opened, the potential for energy loss increases substantially. This is where today’s sensors come into play, monitoring door activity and even triggering alerts if doors remain open too long.

Commercial Refrigeration

Commercial refrigeration significantly increases energy usage, and if efficiency concerns are not properly addressed, substantial waste is possible. To overcome these issues, commercial refrigerators tend to include high-efficiency electronically commutated motors, along with anti-sweat heaters that limit condensation and uniquely efficient compressors that promote variable-speed operation.[12]

Fan Controllers and Condensing Pressure

Fan controllers determine how fans operate within refrigeration systems. When these operate efficiently, they can boost airflow and even extend the fan’s lifespan. Meanwhile, precise management of the condensing pressure drives efficient heat transfer and limits overload. This may encompass electronic expansion valves (EEVs), which help to control the flow of refrigerant.

Residential Refrigeration

While residential units can achieve extraordinary efficiency, this is often limited by residents’ lack of awareness regarding the impact of their everyday habits — and, for many, their poor commitment to cleaning and maintenance.

Cleaning, Placement and Proper Loading

One of the simplest and most impactful steps for improving refrigeration efficiency? Clean the condenser coils. If dirt or dust accumulates, it could potentially act as an insulator, forcing refrigeration systems to work even harder.

Unit placement is also impactful, as it can be difficult for units to release heat if they are placed in cramped areas. Furthermore, loading within the refrigerator must be considered, with overloading prompting uneven cooling via restricted circulation, while underloading forces systems to cool far more space than is actually required.

Common Questions About Refrigeration Cycle

How long should a refrigerator run between cycles?

Refrigerators tend to run about half an hour per cycle, although this can vary considerably according to room temperature and fridge contents. In general, anywhere between twenty and forty minutes is reasonable.

How long is the defrost cycle on a refrigerator?

Automatic defrost cycles may span up to half an hour, although with some fridges, this may take less than fifteen minutes. Defrosting typically takes place once or twice per day. The goal is to limit frost buildup without allowing food temperatures to rise excessively.

How often should a refrigerator cycle on and off?

Most refrigerators cycle on and off between five and eight times per day. This ensures consistent cooling but avoids overworking the compressor. Excessive cycling may indicate concerns such as poor sealing or dirty condenser coils.

Promote Efficient Heating, Cooling and Refrigeration: Discover the Secrets to Energy Efficiency With SJVC

Discover the secrets behind refrigeration efficiency as you prepare for a career that makes a huge difference in your community. SJVC can guide this journey. Our Heating, Ventilation, Air Conditioning and Refrigeration (HVAC-R) program introduces you to refrigeration fundamentals: heat transfer, recovery-recycle-reclaim and so much more.

At SJVC, we offer a hands-on approach to HVAC-R coursework, ensuring you not only understand the theories that underscore refrigeration, but also that you can actively build these concepts into diagnostics and repairs. Get started today so you can bring reliable refrigeration to local homes and businesses.

Sources:

[1] Hautzinger, D. “How the Miracle of Refrigeration Changed Our Food System – And Chicago’s Role in Its Development.” WTTW. www.wttw.com/playlist/2024/07/11/frostbite-nicola-twilley

[2] U.S. Energy Information Administration. “Table HC3.1 Appliances in U.S. homes, by housing unit type, 2020.” www.eia.gov/consumption/residential/data/2020/hc/pdf/HC%203.1.pdf

[3] Torr Engineering. “The Refrigeration Cycle.” www.torr-engineering.com/the-refrigeration-cycle/

[4] Physical Chemistry. “Supercooling and Superheating.” www.youtube.com/watch?v=VfyTELj5cOQ

[5] Fantastic Fridges. “Getting Superheat and Supercooling.” www.fantasticfridges.com/AdvancedTopics/GettingSuperheatAndSubcooling

[6] Institute of Refrigeration. “Measuring Superheat.” www.fantasticfridges.com/content/cms/files/GettingSuperheatandSubcooling/Basics%20-%20measuring%20superheat.pdf

[7] U.S. Food and Drug Administration. “Refrigerator Thermometers – Cold Facts about Food Safety.” www.fda.gov/food/buy-store-serve-safe-food/refrigerator-thermometers-cold-facts-about-food-safety

[8] Bailey, J. “The Importance of Controlling Head Pressure.” ACHR News. www.achrnews.com/articles/152866-the-importance-of-controlling-head-pressure

[9] Evans, P. “Refrigeration cycle, essential knowledge.” The Engineering Mindset. theengineeringmindset.com/the-refrigeration-cycle-essential-knowledge/

[10] LG. “Why Does a Refrigerator Need a Compressor?” www.lg.com/global/business/compressor-motor/blog/why-does-refrigerator-need-compressor

[12] Energy Star. “Commercial Refrigerators & Freezers.” www.energystar.gov/products/commercial_refrigerators_freezers