Modern HVAC-R isn’t just about heating and cooling — it’s one piece in a larger puzzle that aims to boost comfort and efficiency. A lot goes into this effort, and while human expertise is certainly important, automated solutions also have a powerful role to play. Through automation, we can draw on a wealth of data to determine when or how spaces require heating or cooling adjustments.

Modern HVAC-R isn’t just about heating and cooling — it’s one piece in a larger puzzle that aims to boost comfort and efficiency. A lot goes into this effort, and while human expertise is certainly important, automated solutions also have a powerful role to play. Through automation, we can draw on a wealth of data to determine when or how spaces require heating or cooling adjustments.

Today’s intelligent systems draw on details, but also maintain a big-picture approach, drawing on changes in equipment performance or human behaviors to inform overarching HVAC operation. The result? Dramatic efficiency improvements, not to mention consistent comfort and even personalization.

The opportunities are already impressive, but despite the tech-driven nature of these HVAC-R controls and building automation systems, a strong need for human expertise remains.

This is where HVAC technicians come into play. Drawing on fundamental principles (like thermodynamics and heat transfer) but also incorporating cutting-edge technologies, today’s technicians blend mechanical and digital expertise to realize the full potential of automation. Keep reading to learn more about technicians’ work with HVAC controls and building automation systems.

What Are HVAC Automation Controls?

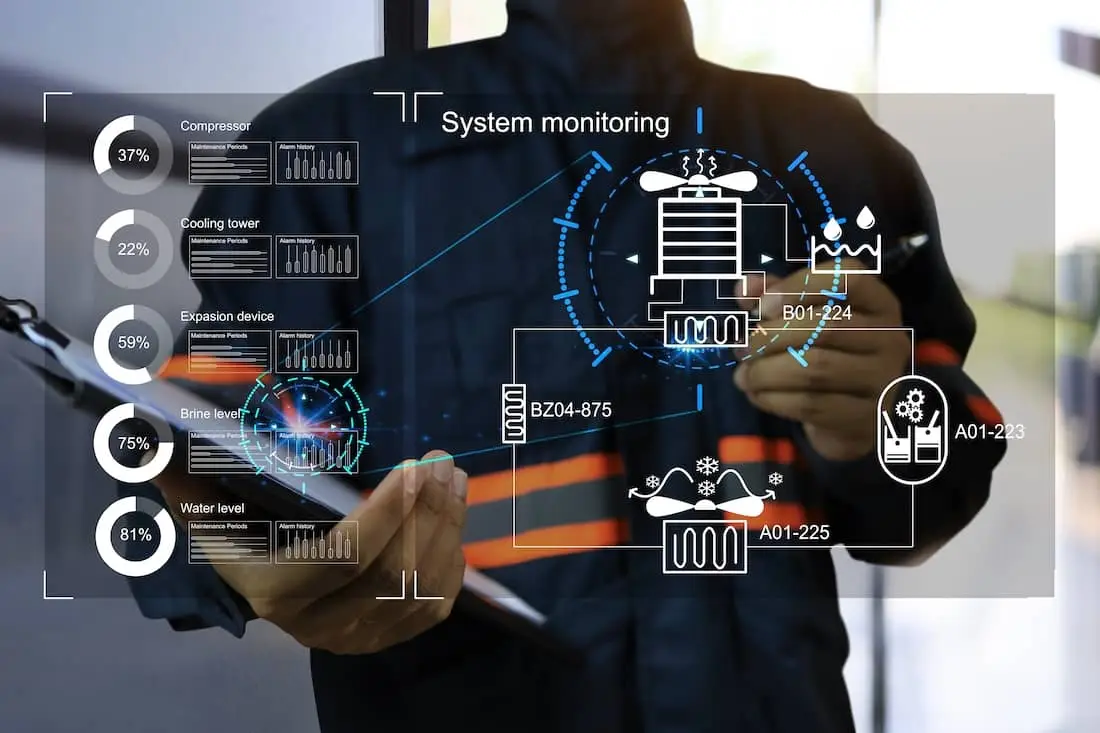

HVAC controls regulate temperature, humidity and airflow. Targeted controls monitor and adjust these elements as needed to create a desired indoor environment. These systems rely on a series of sensors and thermostats but may also incorporate building automation technologies.[1]

Although automation controls rely on differing mechanisms, they share several common goals: improving performance and comfort by responding to evolving conditions, while also enhancing efficiency by minimizing unnecessary energy consumption.

What Are the Types of Automation Controls in HVAC?

There are many approaches to automating HVAC systems. These automated solutions can be classified based on how various systems determine the need for heating or cooling, or according to the physical equipment that powers these systems. We will discuss both elements of control in detail below.

On/Off

Units are powered on when the thermostats reach a specific temperature. Similarly, they’re powered off once specified temperatures have been exceeded. Many homeowners, for example, set their furnace to power on once the temperature becomes too cold, allowing it to power off once set temperatures then are reached.[2]

Although this may seem simple at first glance, it qualifies as automation when the need to manually switch controls on or off is removed.

Proportional Control

In a proportional control system, the unit operates either slower or faster depending on the temperature that has been reached within a defined range.[3] In the summer, this is driven by the intense effort units exert to cool interior spaces.

For example, if the unit only needs to cool the room by one degree, the fan will operate more slowly. If there’s a seven-degree difference, the fan will work harder to reach the set temperature quickly. The response to reaching the desired temperature is proportional and therefore, closely linked to the difference the unit needs to make up.

Integral Control

Offering a uniquely precise method for controlling units, integral controls observe when spaces are too hot or too cold, fine-tuning systems accordingly to achieve and maintain the desired temperature. While proportional control may allow for modest temperature variations, integral control aims to maintain specified temperatures at all times.

Derivative Control

Older HVAC systems often fluctuate wildly between too hot and too cold. These systems may benefit from derivative control. This monitors the rise or fall of temperatures and adjusts the heating or cooling speed accordingly. If a room appears to cool quickly, the derivative control will make adjustments to slow down the rate of cooling until the desired temperature is reached.

The previously discussed proportional, integral and derivative functions can be integrated to form an advanced strategy known as PID control, allowing for automatic adjustments that incorporate both predictive and self-correcting elements.[4] This offers an intelligent alternative to strictly on/off automation, which, by comparison, is highly reactive and far less precise.

What Are the Main Types of Automation Technologies in HVAC?

We’ve discussed the control strategies that determine how or why systems respond to changes in temperature — and we’ve explained an answer to the question “What are the four types of automation controls in HVAC?”

From the HVAC technician’s perspective, however, these systems must also be described in terms of the technologies they incorporate.

These additional classifications primarily result from recent advancements, moving from the pneumatic systems of yesteryear towards advanced solutions involving direct digital controls (DDC) or hybrid options.

Direct Digital Controls (DDC)

Using advanced sensors and digital processors, direct digital controls place entire HVAC systems at users’ fingertips. These cutting-edge systems promise precise monitoring and control, drawing on real-time information to make small, but meaningful adjustments that can boost comfort while also delivering impressive gains in efficiency.[5]

Continuous monitoring and built-in diagnostics further enhance the appeal of DDC, bringing a uniquely proactive approach to maintenance, and ultimately, limiting HVAC downtime. These integrate seamlessly with building management and automation systems to provide all-around optimization through centralized control.

Electric Controls

While electric HVAC controls feature simpler designs than their modern DDC siblings, they offer some benefits in terms of efficiency and performance. These controls function as simple on/off switches, providing the necessary power to enable HVAC systems to heat or cool spaces as needed. Electric controls then cut power once the desired temperature has been reached.

Each electrical control system functions by using relays (for smaller loads) and contactors (for larger loads) to turn switches off and on. Reliable and easy to implement, these offer low-cost solutions that capture the benefits of automation without requiring complex infrastructure or programming.

Pneumatic Controls

Pneumatic controls use compressed air instead of electricity to operate HVAC systems. When the thermostat senses a need for either warm or cool air, it sends a signal to the compressor, which uses compressed air to open the pneumatic actuator that controls the amount of hot or cold water running to the radiator or heating coil.

These controls are not typically found in newer systems. However, HVAC technicians must still be familiar with them, as many are still required to provide maintenance or troubleshooting services within older structures.

Hybrid Systems

Hybrid HVAC systems blend pneumatic processes or components with modern electrical systems. These are often found within older buildings, especially when major HVAC overhauls are deemed unrealistic.

Under this hybrid approach, older pneumatic components work in tandem with retrofitted electric controls, bringing the benefits of electric automation to the forefront. Some hybrid systems may even incorporate direct digital control interfaces to maximize energy efficiency. Keep in mind that with HVAC, the term ‘hybrid’ may also refer to systems that include electric heat pumps and gas furnaces.

HVAC Automation in Practice: From Smart Homes to Smart Buildings

Energy conservation isn’t just good for the planet. It’s also great for the bottom line. To reduce energy bills, businesses and homeowners may consider HVAC automation to ensure optimal heating and cooling without compromising efficiency.

Automation can prove valuable within many settings, ranging from large-scale industrial structures to single-family homes. The mechanisms that underscore these temperature controls can vary dramatically, however, reflecting differences not only in electricity and controls for HVAC/R, but also according to various building sizes or occupancy patterns.

Smart Thermostats: Automation for the Modern Home

Many people find it difficult to strike the right balance between comfort and efficiency, especially if they prefer to “set it and forget it” rather than make incremental changes throughout the day. That said, the smart thermostat has taken all the guesswork out of the equation, sensing temperatures within various spaces and making adjustments accordingly.[6]

Devices like Nest and Ecobee have revolutionized home comfort by incorporating innovative features like geofencing. These thermostats can sense when residents return home and make needed changes based on such arrivals or other resident behaviors.

Building Automation Systems (BAS): Integrated Control for Commercial Spaces

Building automation systems act as the nerve center of contemporary structures. These control everything from security systems to lighting, and, of course, HVAC controls.[7]

BAS utilizes advanced computer networks that can interface with every aspect of the HVAC system, allowing for maximum energy efficiency and increased system reliability. These are primarily found within commercial spaces, where they provide centralized control, along with the opportunity to significantly reduce operational expenses.

The Benefits of Mastering HVAC Automation

HVAC automation is poised to become the new standard in heating and cooling. By mastering HVAC automation, technicians and specialists can offer enhanced services for their clients, driving greater satisfaction while allowing both businesses and homeowners to enjoy major improvements in efficiency. Advantages worth noting include:

Unparalleled Energy Efficiency

Automated HVAC systems make it easy for anyone armed with a smart thermostat or direct control device to save money on their utility costs. HVAC technicians can help clients boost efficiency by configuring automated systems that determine how spaces are heated or cooled amid changing conditions.

These systems may also be designed to respond dynamically based on occupancy, thereby limiting the potential to waste energy to heat or cool unoccupied areas. These systems also optimize runtime, only operating as long as actually needed to improve interior comfort.[8]

Enhanced Comfort and Air Quality

Older HVAC systems that struggle to keep up with energy demands can cause spaces to feel downright inhospitable. Temperature isn’t the only concern; air quality can also suffer due to inefficient HVAC operations.[9]

If, for example, ventilation is not properly managed, particulate matter could accumulate. This may include dust, dirt or even smoke. Automated HVAC systems, however, are well-suited to remove particulate matter from interior air, adjusting airflow as needed and also making the most of high-level filters.[10]

Predictive Maintenance and Diagnostics

Preventive maintenance limits costly downtime by addressing concerns before they cause complete system failures.[11] Modern smart HVAC systems incorporate diagnostic features that can detect hardware issues or performance concerns in real time, catching early warning signs that help technicians order the right parts or schedule repairs in advance.

Your Future in HVAC-R: From Technician to Automation Specialist

As HVAC controls and building automation systems continue to evolve, there will be a strong need for multi-talented installers, technicians, and mechanics who can navigate a wide range of heating and cooling solutions.

SJVC provides well-rounded preparation for tackling HVAC opportunities and challenges. Curriculum explores installation, operation, maintenance and repair of both residential and light commercial heating, ventilation, air conditioning and refrigeration equipment and systems. Embrace the future of HVAC and learn more about SJVC’s Heating, Ventilation, Air Conditioning and Refrigeration program.

Sources:

[1] Holstein, S. “What are HVAC controls and how do they work?” Computrols. https://www.computrols.com/how-does-hvac-control-system-wo,rk/

[2] Eaton. “On/Off control for HVAC control.” https://www.eaton.com/us/en-us/products/controls-drives-automation-sensors/industrial-control-center/automation-control/hvac-control/on-off-control.html

[3] Eaton. “Proportional, Integral, Derivative (PID) control for HVAC control.” https://www.eaton.com/us/en-us/products/controls-drives-automation-sensors/industrial-control-center/automation-control/hvac-control/pid-control.html

[4] Engineered Air Balance. “PID Control for HVAC Systems.” https://www.eabcoinc.com/training-center-news/pid-control-for-hvac-systems/

[5] Therma. “Benefits of Direct Digital Control.” https://www.therma.com/benefits-of-direct-digital-control/

[6] Energy Star. “Smart Thermostats.” https://www.energystar.gov/products/smstruggle to strike the right balance between comfort and efficiency, especially those who prefer to “set it and forget it” rather than make incremental adjustmentsart_thermostats

[7] International Manufacturing Technology Show. “Introduction to building automation systems.” https://www.imts.com/read/article-details/Introduction-to-building-automation-systems/1946/type/Read/1

[8] Mistry, V. “Energy Efficiency in HVAC Systems through Building Automation.” Journal of Biosensors and Bioelectronics Research. https://www.researchgate.net/publication/378452868_Energy_Efficiency_in_HVAC_Systems_through_Building_Automation

[9] Mistry, V. “Impact of Building Automation on Indoor Air Quality and HVAC Performance.” Journal of Artificial Intelligence & Cloud Computing. https://www.researchgate.net/publication/378416265_Impact_of_Building_Automation_on_Indoor_Air_Quality_and_HVAC_Performance

[10] Dallo, F. et al. “Using smart thermostats to reduce indoor exposure to wildfire fine particulate matter (PM2.5).” Indoor Environments. https://www.sciencedirect.com/science/article/pii/S2950362025000177

[11] Es-sakali, N. et al. “Review of predictive maintenance algorithms applied to HVAC systems.” Energy Reports. https://www.sciencedirect.com/science/article/pii/S2352484722013944