Interested in a hands-on career where you maintain and repair aircraft? Then a career as an aviation mechanic and service technician might be the right fit for you. Read on to learn the ins and outs of a career in aircraft maintenance, and how you can get started.

What do aircraft mechanics and service technicians do?

Aviation mechanics and service technicians are tasked with repairing and performing scheduled maintenance on aircraft. According to the Bureau of Labor Statistics (BLS), aircraft mechanics and service technicians typically do the following:

- Diagnose electrical and mechanical problems

- Repair electrical systems, wings, brakes, and other components of an aircraft

- Use power tools and hand tools to replace defective parts

- Examine replacement aircraft parts for any defects

- Identify repair procedures by reading maintenance manuals

- Use gauges and other diagnostic equipment to test aircraft parts

- Inspect completed work to make sure it meets performance standards

- Keep records of repair and maintenance work

What are the benefits of an aircraft mechanic career?

Working as an aircraft mechanic has several benefits. One pro to this career is that employment in aviation maintenance is expected to be relatively steady for the next several years. The BLS projects that employment of aircraft mechanics will grow 5 percent from 2016 to 2026, which is about as fast as the average of all occupations. This is due to the expectation that air traffic will increase at a gradual pace over the next decade, so more aircraft maintenance will be needed, including maintenance done on newer aircraft.

How much do aircraft mechanics make?

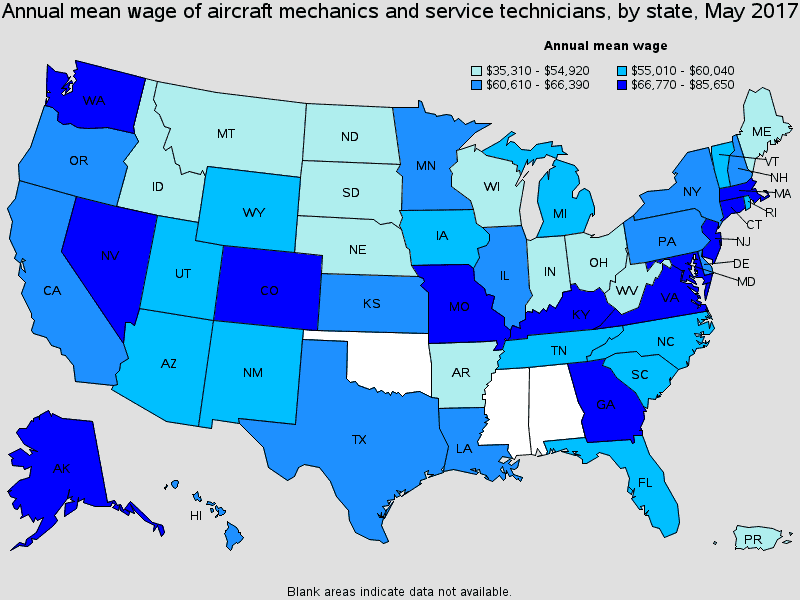

Another plus to an aircraft mechanic career is decent pay. The BLS reports that the median annual wage for aircraft mechanics and service technicians was $61,020 in May 2017. In California, aircraft mechanics earn an annual mean wage between $60,610 – $66,390, per the BLS:

Where do aircraft mechanics and service technicians work?

Aircraft mechanics typically work in hangars, at repair stations or on airfields, all of which are usually near major airports.

Is a career as an aircraft mechanic right for me?

Even if you don’t have previous mechanic experience, but have a solid interest in an aircraft mechanic career and the determination to pursue it, it could be a great fit for you! It is important to take your aircraft maintenance training seriously, however. Aircraft mechanics work on tight deadlines, and need to have a high attention to detail. Maintaining and repairing civilian and military aircraft requires mechanics who are focused and efficient, as errors could cause aircraft to malfunction.

The BLS lists the following as important qualities a person should have to work successfully in aircraft maintenance:

- Detail oriented. Mechanics and technicians need to adjust airplane parts to exact specifications. They often use precision tools to tighten wheel bolts to a specified tension.

- Dexterity. Mechanics and technicians need to coordinate the movement of their fingers and hands in order to grasp, manipulate, or assemble parts.

- Observational skills. Mechanics and technicians must recognize engine noises, read gauges, and collect other information to determine whether an aircraft’s systems are working properly.

- Strength. Mechanics and technicians may carry or move heavy equipment or aircraft parts, climb on airplanes, balance, and reach without falling.

One last thing to keep in mind if you’re considering this career:

The rate of injuries and illnesses that aircraft mechanics and service technicians experience is higher than the national average for all occupations because, according to the BLS, mechanics and technicians are often operating large power tools, lifting heavy objects and handling dangerous chemicals. They could be working on scaffolds or ladders, with loud noise and vibrations being common place especially with aircraft engines. So as a mechanic or technician, you will need to take precautions against injuries, such as wearing ear protection and brightly covered vests so that you can be seen when working with large aircraft.

Requirements for being an aircraft mechanic

Do I need to be licensed and certified to work as an aircraft mechanic?

Yes. The Federal Aviation Administration (FAA) requires that aircraft maintenance be done either by a certified mechanic with the appropriate ratings or authorizations, or under the supervision of such a mechanic.

The FAA offers separate certifications for bodywork (Airframe mechanics, or “A”) and engine work (Powerplant mechanics, or “P”), but employers may prefer to hire mechanics who have both Airframe and Powerplant (A&P) ratings. The A&P ratings generally certify that aviation mechanics meet basic knowledge and ability standards, according to the BLS.

According to the balance, if you’re interested in a career as an A&P mechanic, you will need to be at least 18 years old and able to speak, read, write and understand English to qualify for an A or P, or A&P license. You will also need at least 18 months of on-the-job experience working on either Airframe or Powerplant or at least 30 months of experience on both Airframe and Powerplant to get both certifications.

If you’re in the military, the FAA does give credit for time spent maintaining aircraft during your service.

Another option is to graduate from an FAA-approved school for maintenance to substitute for the experience requirements.

How do I start my aircraft mechanic training?

To begin your training, you can enroll in SJVC’s Aviation Maintenance Technology (AMT) program, which is approved by the FAA, U.S. Department of Transportation.

SJVC’s aircraft mechanic program prepares students with the skills and technical knowledge they need to perform maintenance on aircraft airframe (body) and powerplant (engine). In addition to classroom instruction, hands-on training in the hangar includes maintenance, servicing, troubleshooting, and repair of airframe and powerplant systems and components.

Students can earn a Certificate of Completion in approximately 17 months, or an Associate of Science degree in approximately 22 months. Graduates are prepared to test for an Airframe and Powerplant (A&P) license through the Federal Aviation Administration (FAA).

Give us a call at (866) 544-7898 or request information to get started.